Rigorous Watch Testing and Inspection

All incoming material and components are carefully tested in our factory. With a strict total quality management system in place and a whole set of testing machines, we ensure all OEM watches including OEM women's watch and OEM men watch comply with our standards before delivery. Before the dispatch of an OEM watch, it is checked for accuracy, reliability and water resistance according to strict company guidelines. Every part, half-finished watch, and the complete watch will be subjected to strict quality inspections of appearance by our IQC/QC/FQC. Each batch of your custom brand watches will undergo function quality tests such as UV test/twisting force test/abrasion test/push button test/swing test/ burn test etc. Partner with GoTop to get high-level quality standards.

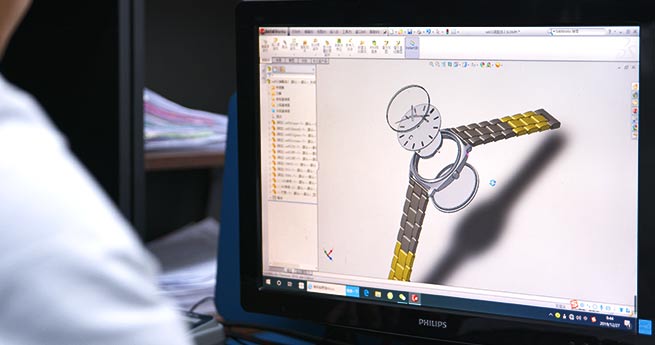

Dedicated to the highest standards, GoTop selects only the finest materials, sourcing proven quartz and mechanical mechanisms, delivering exceptional performance and reliability for every client. With a 100,000-grade dust-free assembly workshop and on-site fabrication facilities, we offer the complete, end-to-end watch manufacturing solution for clients of all sizes of watch OEM.

To ensure that consumer safety and protection of our client's brand is met, all our watches delivered to Europe are RoHS & REACH Compliant.